Store Location: 114 Holloway Road, Aro Valley, Wellington, Wellington

info@oceanicglassinnovations.com

+6498899268

Head Office: 83 Rushdale St, Knoxfield VIC, 3180, Australia

+61 485 814 909

With Glass selection, there are several key factors that determine what glass to use:

The first two factors are required by law via Building Codes and referenced Standards. The personal preferences can include the aesthetic look or colour of glass, high clarity seeing through the glass or privacy, further acoustic desires or protection from intrusion. Below we look at these three main factors in greater detail.

The National Construction Code (NCC) dictate a buildings Total System U-Valuew and SHGCw

for its Glazing. The Glazing refers to Glass + Frame + Sealants. U-Valuew focuses on the

Insulation factors of the glazing (how much inside-heat it can stop from escaping out when

it is colder outside). This therefore relates to the required Heating Load energy used by a building when it is cold to keep the

inside temperature a warmer, healthier and more comfortable level. SHGC (Solar Heat Gain Coefficient) focuses on how much heat from the Sun enters inside through the glazing when it is hot and sunny outside. This therefore relates to the Cooling Load energy used by a building when it is hot to keep the inside temperature a cooler, healthier and more comfortable level.

The requirement to meet these minimum performance factors is our first point of call when selecting glass and glazing. For proven Total System performance values using our glass types,

see our AGG Estimated Total System Performance Data document,

or our Speckel Glazing System Calculator, or our WERS section.

Other required performance factors include:

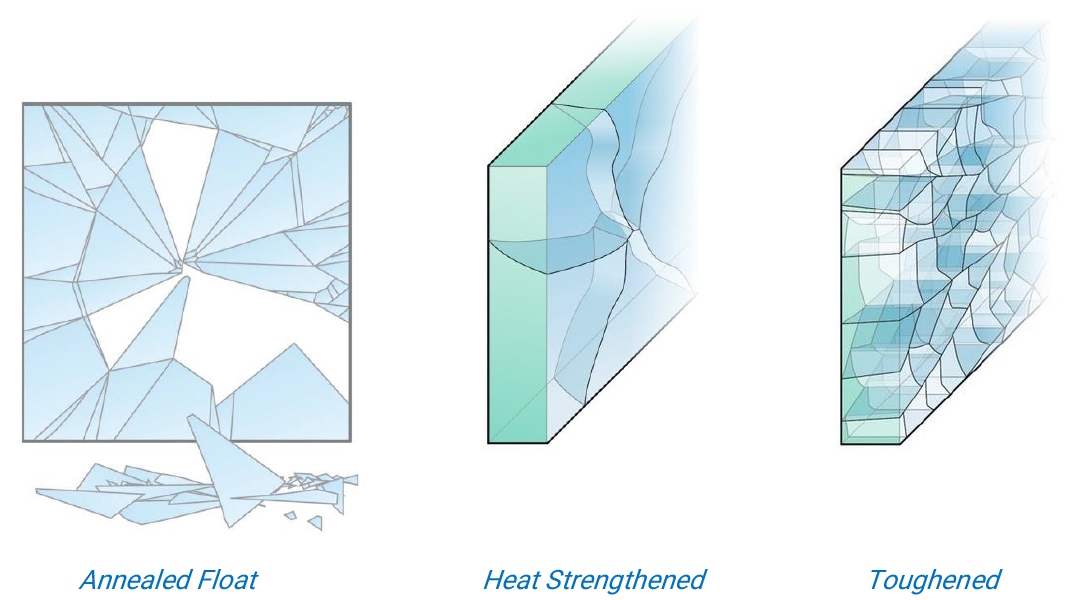

Additional strength may be required in glass due to sizes of units, wind loads and human impact factors. Regular annealed float glass can be heat treated for this by either Heat Strengthening (HS) or fully Toughening (TGH), which is also known as Tempering. If you line up the three types of glass types as per the images below, you may be able to break the Annealed Float glass by throwing a stone at it with minor strength and if it breaks, it will break as very sharp and dangerous shards of glass.

The Heat Strengthened glass can be 2x stronger and so now that stone may need a lot of force behind it to break, and if it breaks it will break into larger pieces that are not as sharp but still dangerous. The Toughened unit can be up to 5x stronger than the Annealed glass and may require a brick thrown at a lot of force to break it, and if it breaks is shatters into thousands of small, unsharp, safer pieces of glass.

Spontaneous Combustion is the explosion of Toughened glass due to an inclusion, like Nickel Sulphide. These inclusions can exist in the glass from its original raw materials (eg. sand) and gets primed/enlarged during the Toughening process. This can result in the Toughened glass exploding at any future point in time, even years later.

If the glass remains intact (seen in Toughened laminate) you will see a noticeable ‘butterfly’ pattern of the break style that centres around the inclusion that can be seen as a dark dot with the naked eye (see image below).

To minimise this risk, you can avoid the use of Toughened glass, or if Toughened glass is required you can Heat Soak the Toughened glass.

Get In Touch With Us

info@oceanicglassinnovations.com

+6498899268

+61 485 814 909