Store Location: 114 Holloway Road, Aro Valley, Wellington, Wellington

info@oceanicglassinnovations.com

+6498899268

Head Office: 83 Rushdale St, Knoxfield VIC, 3180, Australia

+61 485 814 909

It is important to note that when we state ‘Glazing’ we are not talking about the Glass alone. Glazing is the Glass + Frame + Sealants + Hardware as well as any Screens (if used).

The supply chain of glass can be simplified by starting ‘Upstream’ with the raw material glass manufacturer (a Float Plant) and as it travels ‘Downstream’ it gets value added to it at each step; first by a Glass Processor and then by a Window Fabricator until the final product is used (windows and glass doors).

When we start with regular glass used in buildings, we are using Soda-Lime-Silicate glass which is manufactured by a ‘Float Plant’. There are several names for this glass: Clear Glass, Float Glass, Clear Float Glass, Float, Annealed Glass. It is made up of raw ingredients including:

These ingredients are furnaced and mixed in around 1,600 degrees Celsius, refined and then pulled across a bed of molten Tin at a lower temperature of around 1,100 degrees Celsius. It is here where Physics see the material ‘float’ across the tin as it is pulled across it, making it flat. The red hot material is then cooled via the annealing process of blowing colder air onto it,

putting enough stress in the glass to make it what we know as regular annealed/float glass.

A float plant can manufacturer:

We call these the ‘raw material’. A float plant can also add more value before it is annealed by adding a rolled pattern (similar to a pasta maker) or spraying on a Hardcoat LowE coating.

A Glass Processor, like Australian Glass Group, takes these raw materials and adds further value by processing the glass. A Glass Processor can:

A Window Fabricator then completes the added value by fabricating the processed glass units into full windows and doors using a frame system, seals and installation. The main material fabricators use for the frame system include:

A Glass Processor will process glass based on the needs and applications of the glass. Four key needs include:

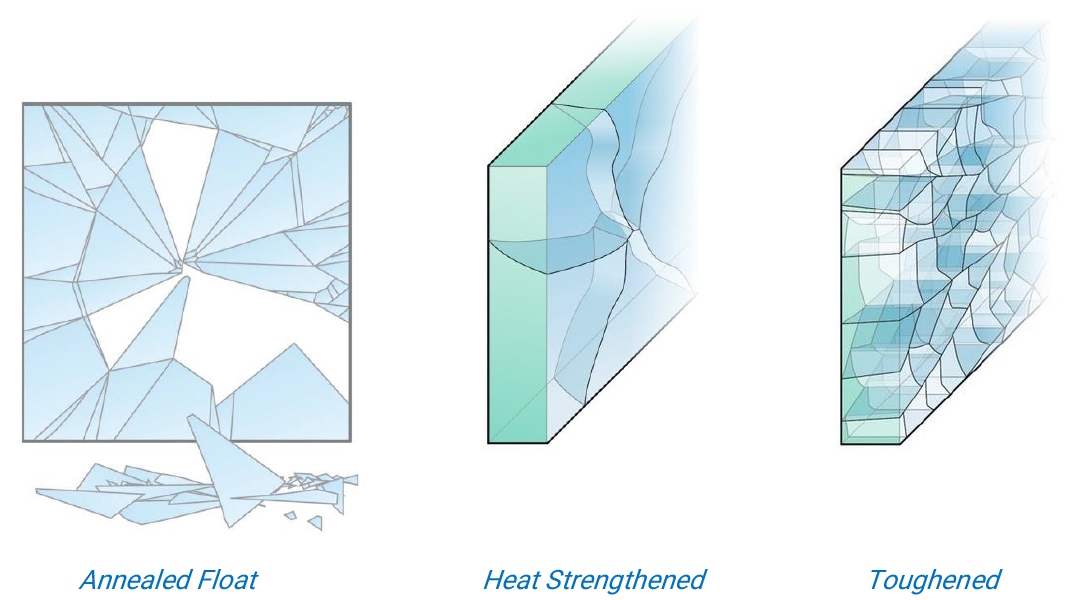

Additional strength may be required in glass due to sizes of units, wind loads and human impact factors. Regular annealed float glass can be heat treated for this by either Heat Strengthening (HS) or fully Toughening (TGH), which is also known as Tempering. If you line up the three types of glass types as per the images below, you may be able to break the Annealed Float glass by throwing a stone at it with minor strength and if it breaks, it will break as very sharp and dangerous shards of glass.

The Heat Strengthened glass can be 2x stronger and so now that stone may need a lot of force behind it to break, and if it breaks it will break into larger pieces that are not as sharp but still dangerous. The Toughened unit can be up to 5x stronger than the Annealed glass and may require a brick thrown at a lot of force to break it, and if it breaks is shatters into thousands of small, unsharp, safer pieces of glass.

Spontaneous Combustion is the explosion of Toughened glass due to an inclusion, like Nickel Sulphide. These inclusions can exist in the glass from its original raw materials (eg. sand) and gets primed/enlarged during the Toughening process. This can result in the Toughened glass exploding at any future point in time, even years later.

If the glass remains intact (seen in Toughened laminate) you will see a noticeable ‘butterfly’ pattern of the break style that centres around the inclusion that can be seen as a dark dot with the naked eye (see image below).

To minimise this risk, you can avoid the use of Toughened glass, or if Toughened glass is required you can Heat Soak the Toughened glass.

Get In Touch With Us

info@oceanicglassinnovations.com

+6498899268

+61 485 814 909